Many voltage regulator technologies can correct voltage variations but most are designed for usage in data centers or other light commercial applications where the load and environmental conditions encountered are fairly benign. When computer-grade voltage regulators are used in industrial situations, there are several operational limitations that must be addressed. An industrial-grade automatic voltage regulator is specifically designed for the special challenges and requirements found in manufacturing applications or in situations where the load demands are severe.

What is an industrial power quality application?

While there is not a single definition for an industrial electrical application, it is true that there can be significant differences in the electrical “environment” found in offices, data centers and factories. The electrical characteristics found in industrial applications like machine shops, plastic manufacturers, food processors, commercial printers, etc. can include high load inrush currents, low power factor, significant load swings and significant amounts of harmonic frequencies. Voltage regulation problems account for more than 90% of the power problems seen at most sites.

Regardless of the type, however, an automatic voltage regulator has one critical function – to ensure that the output voltage delivered will be consistent with its load current even when fluctuations happen in the background. This eliminates the damage that fluctuations can cause to appliances, machines, and equipment.

Critical Applications of AVRs

An automatic voltage regulator is used mostly on equipment possessing electronic parts which are sensitive to power surges or power fluctuations such as:

Medical Equipment:

Medical equipment requires high quality power, and a very stable voltage for accuracy of performance.

X-Ray, CT, MRI and other medical electronics demand a stable reliable voltage delivered from the AC power supply. Otherwise, the working life of medical equipment is shortened and their performance compromised. Since medical machines can be critical to patient safety, they must work under optimal power conditions requiring the use of an AVR to ensure a stable voltage.

3D printing:

No other AVR application is likely to be more critical than in 3D printing of medical devices since these devices must meet very high medical standards and exhibit long-term performance.

3D metal printers require energy sources to be delivered in high precision and extremely accurate control to ensure product quality and safety. Most powders used in 3D printing medical devices are volatile and may cause flash fires and explosion due to sparks in open air or intense flame. An automatic voltage regulator ensures that such accidental sparks are prevented. The AVR promotes a longer life expectancy of the 3D printer and protects it from power problems that will degrade its performance.

Machining:

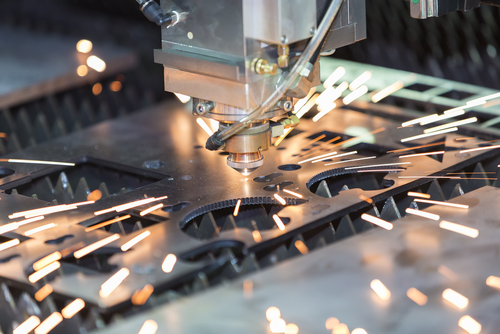

AVRs are necessary to insure high performance of highly automated machines or computer numerical control (CNC) machines. CNC machines are machine tools which are automated by means of computers executing pre-programmed sequences of machine control commands. This is in contrast to machines that are manually controlled by hand wheels or levers, or mechanically automated by the use of cams alone.

CNC machines typically fall into one of the two general categories: conventional machining technologies and novel machining technology:

The conventional technology machines include drill_bitdrills, lathe_bitlathes and milling_bitmilling machines. Novel technologies include electrical and/or chemical machining. There are a number of novel technologies that use specialized techniques to cut material. Examples include electron beam machining, electro-chemical machining, electrical discharge machining, photochemical machining, and ultrasonic machining. Most of these technologies are highly specialized and are used in special cases for mass-production involving a particular type of material. Other cutting mediums use different mediums to cut material. Examples include laser cutting machines, oxy-fuel cutting machines, plasma cutting machines, and water-jet cutting technology.

An example of an application of CNS machines is in the grinding and polishing of optical lenses. With CNC machines, faster and less labor intensive manufacturing methods are now available options to conventional methods. From prototyping to high volume production, automated grinding and polishing technologies are now used for lens fabrication. These new technologies are more efficient and provide more reliable production.

Just like a 3D printer, CNS machines must perform without the power interruption brought on by fluctuations or the entire project will be a failure. The voltage regulator for CNC machines must have the functions of high-frequency interference resistance, anti-surge, and anti-electromagnet. There are many other technical specifications required as well.

Industrial Electrical Application

The electrical power characteristics required in industrial environments are significantly different from those found in offices or in data centers. Plastic manufacturers, food processors and machine shops require high power factor, low inrush currents, low harmonics, and minimum load swings among others.

This is why the automatic voltage regulator used in these environments must be able to prevent and correct the following:

- Large loads & load swings

- High load inrush currents

- High load harmonics

- Low load power factor

Several types of AVRs meeting these requirements are: ferroresonant constant variable transformers (older technology), tap switching transformer, limited range variable transformers, variable transformer buck-boost v.

Staco Energy’s AVR technology is based on a series regulation transformer controlled by variable transformers (VTs). It uses buckboost technology and offers tight output regulation (+/- 1%), robust design and easy customization accommodating against all but the most extreme voltage swings. Were additional non-voltage issues to occur, Staco Energy offers a series of options that address such issues as high voltage transients, high harmonic content and site load imbalance. This integrated and targeted approach provides sites specific power correction in a one-box solution.

Applications for Staco Voltage Regulation

Aside from those listed above include:

Broadcast: regulation for broadcast transmitter sites and studios.

Commercial: high-rise building whole floor regulation or power conditioning, input voltage regulation for elevator control, large a/c chillers lighting, and other sensitive non-critical systems.

Marine: dockside or shipboard voltage regulation and power conditioning.

Mobile: commercial broadcast and military mobile communication trucks, trailers, and shelters.

Please visit our web site or contact us at Peninsula Technical Sales to discuss your particular requirements or any further questions you might have. You can reach us at sales@pentech.com or by calling 650-965-3636.

Peninsula Technical Sales represents electronic equipment manufacturers and is proud to offer our services online and to the following cities and their surrounding areas: San Francisco, Santa Clara, San Jose, Fremont, Sacramento, Milpitas, and Santa Rosa.